IL-45: Testing the cutting properties of milling tools

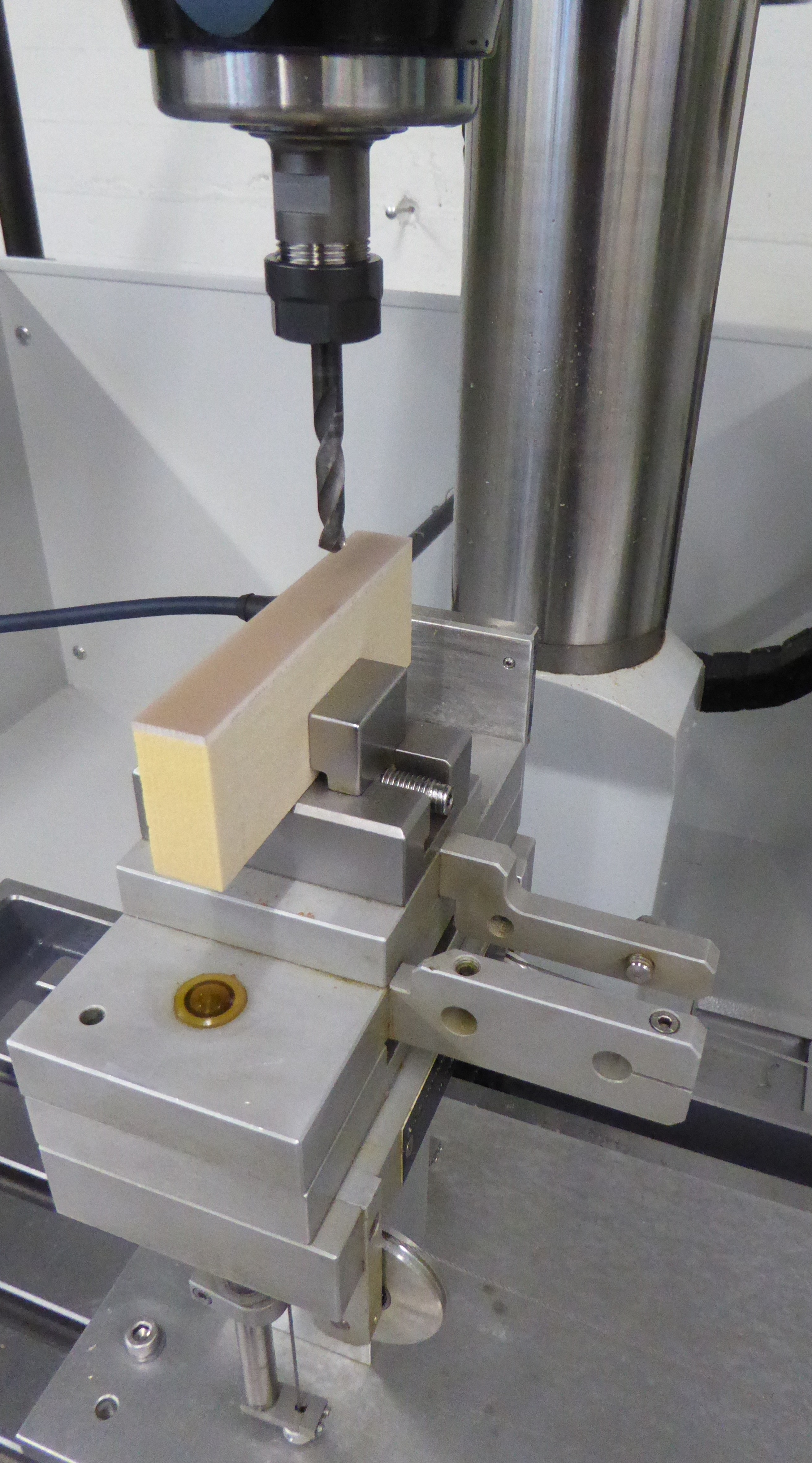

Our new milling test rig allows us to quantify the wear resistance of side cutting tools. This is important not only for manufacturing technology, but also for analysing the wear and cutting properties of surgical instruments. This allows the performance of burr designs to be compared and optimised.

Using the experience gained from many different wear tests on drills (see Newsletter 33), we have developed a test rig for analysing the cutting properties of milling cutters, which makes it possible to compare different cutter designs.

The test rig uses a low-friction cable mechanism to press the material to be machined against the side of the tool with a defined force. A laser distance sensor records the exact distance travelled, which, together with the time measurement, allows the cutting speed of the tool to be accurately calculated. This highly reproducible measurement allows different cutters to be compared in terms of performance and tool life.

Our stable base machine tool is a reliable tool for testing a wide range of materials. Milling tests can be performed on steel, cast iron and aluminium alloys, as well as plastics. In medical applications, for example, we use polyurethane foam bone models reinforced with an epoxy plate to simulate a bone with cortical bone (see Figure 1).

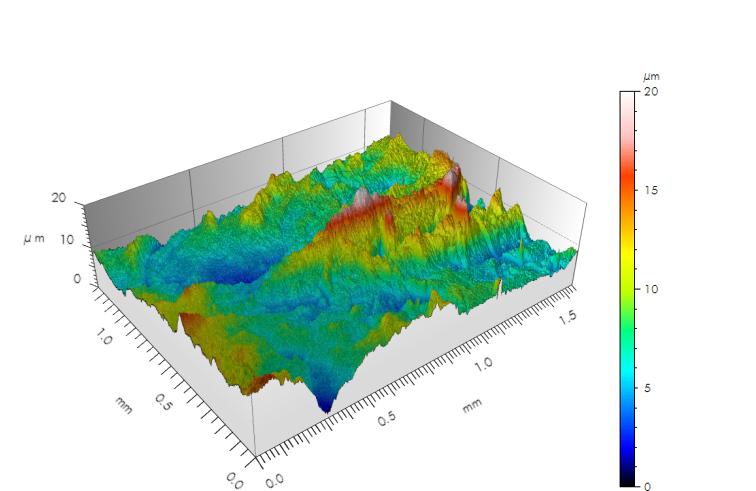

A tried and tested method in our testing practice is to repeatedly perform linear cutting tasks, measuring the change in time required for each pass (see Figure 2). We also often use the test method specified in the Chinese standard YY 91064 for dental drills. First we mill into a PMMA sheet, then into an abrasive material and finally back into a PMMA sheet. The observed increase in milling time provides an important insight into the durability and efficiency of the drill design. This allows decisions to be made on the basis of a solid database.

Information on the structure:

- «Fehlmann Picomax 21-M» machine tool with a maximum speed of 6300 min-1 (infinitely adjustable)

- Tool holders possible via drill chuck or collet chuck

- Maximum width of the sample body: 50 mm

Information on measurement technology:

- Laser distance sensor Opto-NCDT-ILD 1402 from Micro-Epsilon (max. measurable distance: 45 mm)

- Measurement amplifier & software from HBM

![]()

Figure 1: Milling test stand with clamped artificial bone made of a polyurethane foam-epoxy composite material, as typically used in medical technology.

![]()

Figure 2: Typical development of the measured time for machining a defined distance with two different designs of milling tools. The time increases significantly less for type 1, the tool wears more slowly.