IL-43: PMI analysis of metallic and non-metallic materials

Positive Material Identification (PMI) determines whether a material or a component has the required chemical composition. The focus is not on the exact chemical composition, but rather on proving that the material is the correct one. The analyses can be carried out either in the laboratory or in the field using a mobile device.

Optical spark emission spectrometer (OES)

OES provides a rapid chemical analysis of metallic materials, including the elements C, S, N and O. It allows carbon alloy steels to be clearly identified. The analysis is not entirely non-destructive, as an electric arc is generated under argon shielding gas which vaporises the material, leaving a burn mark approximately 10 µm deep and 5 mm in diameter.

![]()

Energy dispersive X-ray spectrometer (ED-XRF)

The ED-XRF can be used to measure metallic materials both in the laboratory and on site. The analysis is non-destructive, which means that the surface of the material is not damaged.

![]()

Wavelength dispersive X-ray fluorescence (WD-XRF)

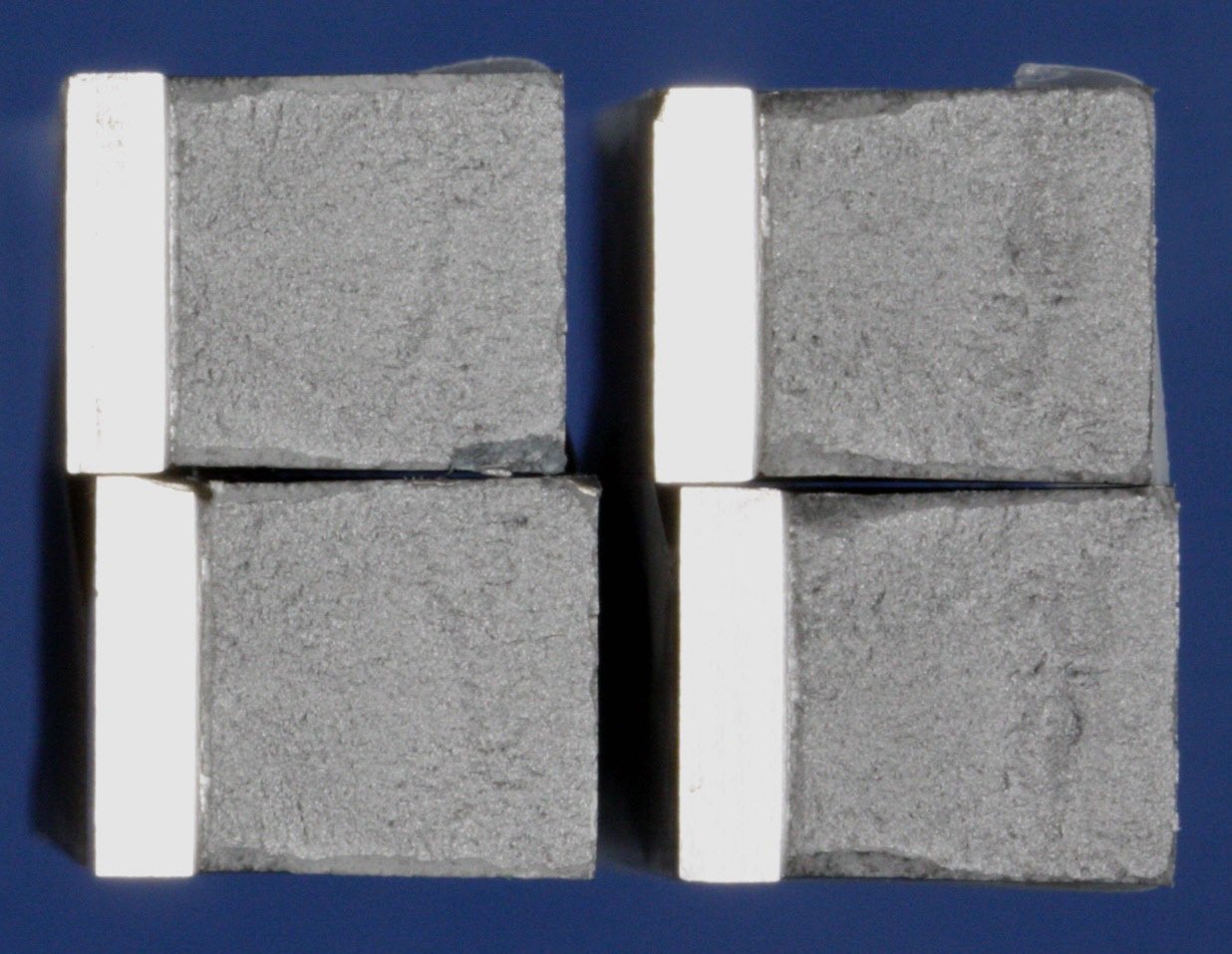

The WD-XRF provides accurate, non-destructive analysis of metallic and non-metallic materials. All materials such as metals, ceramics, glass or cements can be analysed in solid or powder form. The high sensitivity and low detection limits allow the analysis of heavy metals such as lead, cadmium and mercury in compliance with RoHS directives.

![]()

Applications:

- OES: Quantitative elemental analysis including the elements C, S, O and N on metallic materials

- ED-XRF: Stationary and mobile quantitative elemental analysis of metallic materials

- WD-XRF: Qualitative and quantitative elemental analysis of metallic and non-metallic materials

Equipment:

- OES Bruker Q4 Tasman

- ED-XRF Bruker Handheld S1 Titan LE

- WD-XRF Bruker S8 Tiger