IL-42: Monoclinic Phase Content in Y-Stabilized Zirconia (ISO 13356)

Yttria-stabilized zirconia polycrystal (Y-TZP) is an exceptionally hard and tough ceramic material. Under mechanical stress and in humid environments it tends to transform to a mechanically weak monoclinic phase. To guarantee long-lasting integrity, the monoclinic phase content on the surface of Y-TZP implants must be monitored. RMS Foundation now offers ISO 17025 accredited quantification of the monoclinic phase according to ISO 13356:2015.

A brief history of zirconia

When Garvie et al. [1] published an article entitled “Ceramic Steel?” in Nature in 1975, interest in zirconia (ZrO2) for application in skeletal and dental implants was sparked. Due to its exceptionally high hardness, toughness, wear resistance, chemical resistance, and its aesthetic appearance, zirconia seemed to be perfectly suited for load-bearing orthopedic and dental implant components. However, the success story was overshadowed by a series of roughly 400 implant failures between 1988 and 2001 [2], which was associated with a transformation of the tetragonal phase of zirconia to the monoclinic phase at the implant surface. In the following years, research efforts focused on stabilizing the tetragonal phase by chemical modifications, of which the enrichment of ZrO2 with small amounts of Y2O3 emerged as one of the most promising compositions. Nowadays, yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) is a staple material for orthopedic and dental implant development.

Low-temperature degradation

The transformation to the mechanically weak monoclinic phase is promoted by direct contact with water. It causes a local volume expansion which leads to disintegration of the implant surface due to stress and crack formation. A low initial amount of monoclinic phase on the surface is thus key for a maximized lifetime of an implant.

Transformation toughening

Transformation of Y-TZP to the monoclinic phase also occurs as a result of externally induced mechanical stress, for example an impact or the formation of a crack. Interestingly, in these scenarios the same phase transformation blocks the propagation of cracks and is thus a major factor contributing to the exceptionally high toughness of Y-TZP [3].

Quantification of phases

The different phases can be quantified by X-ray diffraction (XRD). However, certain processing steps can result in surface stress which causes distortions in the XRD signal (Fig. 1) and limits the accuracy of the phase quantification. At RMS Foundation, we offer the quantitative analysis of monoclinic phase as an ISO 17025 accredited service. Our method is compliant with ISO 13356 and was optimized to yield accurate results also in the presence of tetragonal signal distortions.

![]()

Figure 1: XRD signals of Y-TZP with (A, B) and without (C) tetragonal (*) peak distortions (+)

Applications:

- Monoclinic phase content of Y-TZP for surgical application according to ISO 13356 sections 4.4.3 and 4.12

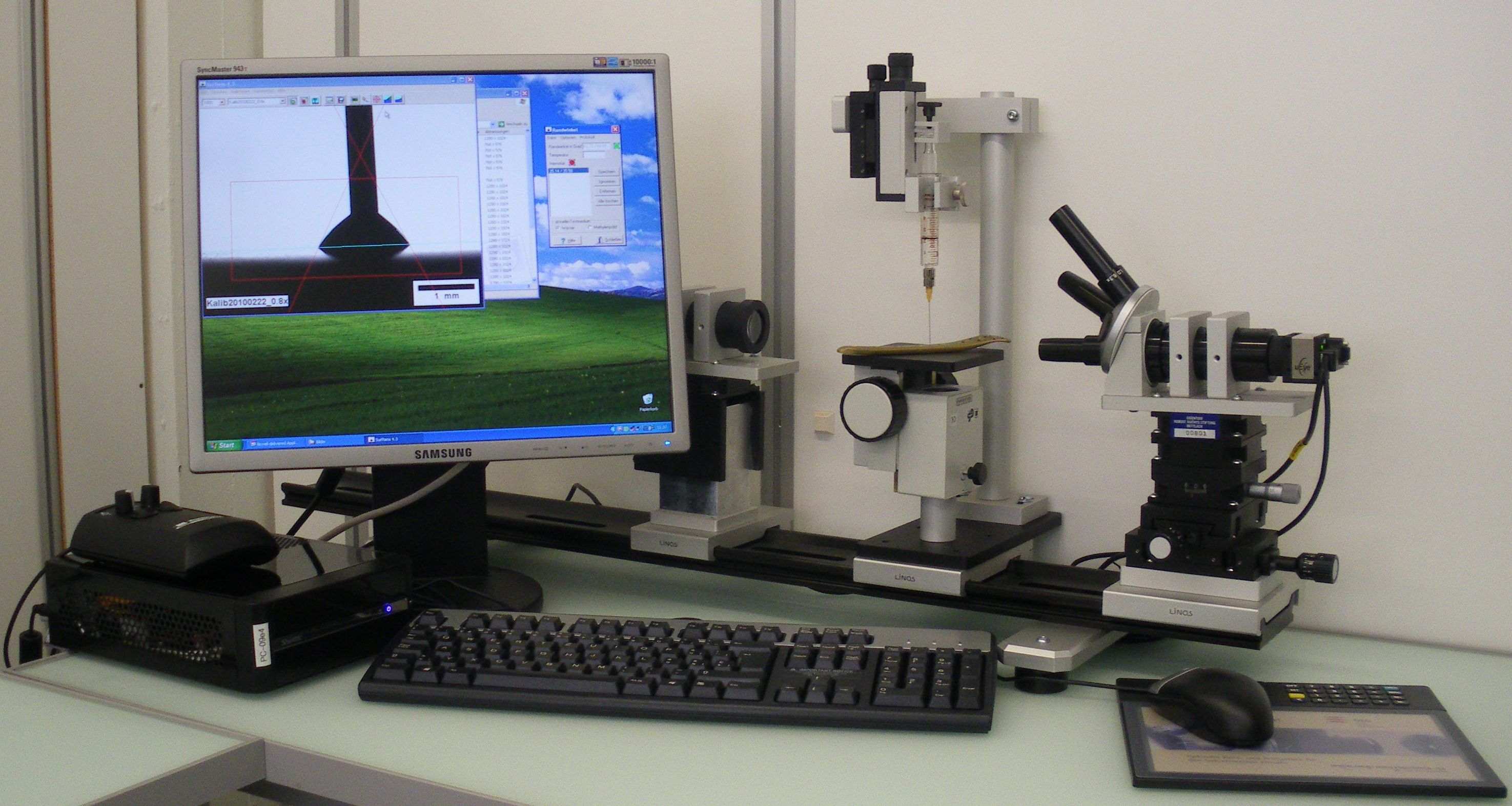

Equipment:

- Bruker D8 Advance X-ray diffractometer

- Systec HX-90 autoklave

Literature:

[1] Garvie, R.C., Hannink, R.H., Pascoe, R. T. "Ceramic Steel?", Nature 1975(258), 703-704.

[2] Guo, X. "Property degradation of tetragonal zirconia induced by low-temperature defect reaction with water molecules," Chem. Mater. 2004(16), 3988–3994.

[3] Piconi, C., Maccauro, G. "Zirconia as a ceramic biomaterial," Biomaterials 1999(20), 1-25.