IL-40: Testing of packaging

Medical products, food and other products are often sealed for air-tight packaging. There are various standardized tests available to verify the quality and leak tightness of the seals or the whole packaging.

RMS Foundation offers the following tests and examinations

Visual inspection (ASTM F1886/F1886M): The seals are visually inspected for their uniformity and possible leaks (channels, under/oversealed areas, wrinkles, cracks, foldovers, etc).

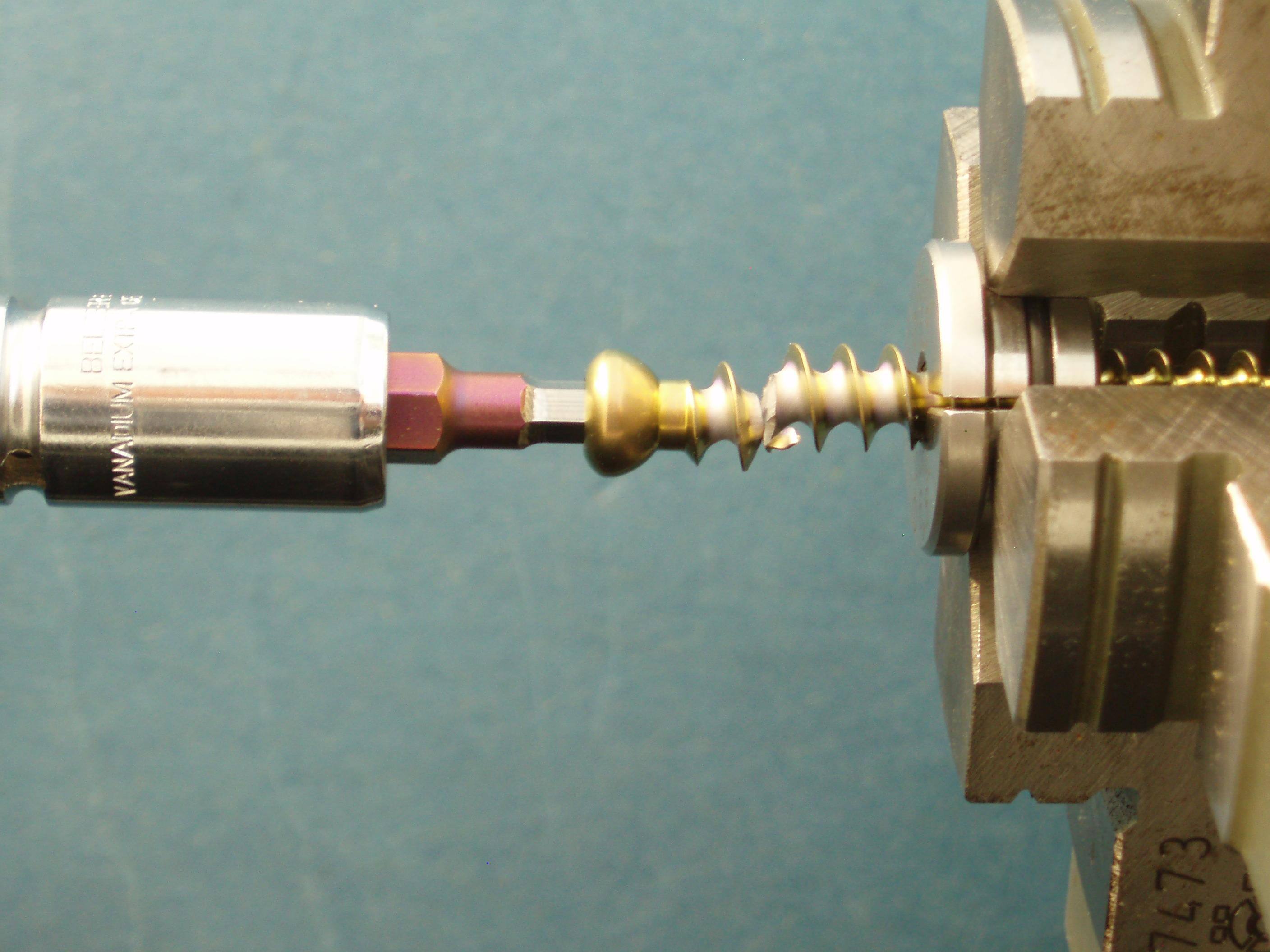

Mechanical seal strength (ASTM F88/F88M, ASTM F2824): On pouches, strips with a width of 15 or 25 mm are cut through the seal and pulled apart during tensile testing. For determination of the main characteristic values, the middle 80 % of the force-displacement curve is evaluated for the maximum (Fmax) and average force (Fmean), necessary to separate both sides of the seal (fig. 1 and 2).

On containers with peelable lids, the lid is pulled-off at an angle of 45° in the tensile test. The maximum and average force, as well as the work is recorded.

Leak testing by dye penetration on non-porous (ASTM F3039) and porous (ASTM F1929) packaging: For both methods, the test liquid is injected into the packaging. Through capillary action channels >50 µm are filled with the test liquid in the seal. The testing liquid and exposure time differ between both standards.

Leak testing by bubble emission (ASTM D3078): The packaging is put in a water bath and submitted to an increasing vacuum. It is recorded at which pressure the packag-ing emits bubbles as sign of leakage.

Burst and creep testing (ASTM F1140/F1140M, F2054/F2054M): For both tests the packaging is put under pressure with pressurized air. For burst testing the maximum pressure, before the packaging fails, is recorded. For creep testing, the pressure is kept constant for a

defined time, or alternatively, the time is recorded at which the packaging fails.

Penetration resistance testing (ASTM F1306, EN 14477): The material of the packaging is clamped in a fixture and slowly perforated with a standardized penetration probe (mandrel). The necessary force, energy and displacement at the first break of the material is recorded.

![]() Figure 1: Sample taken from a pouch, mounted for testing of the mechanical seal strength.

Figure 1: Sample taken from a pouch, mounted for testing of the mechanical seal strength.

![]()

Figure 2: Force/displacement graph with designated Fmax and Fmean.

Packaging types

There are a number of diverse packaging types, e.g. pouches, bowls and cups with peelable lids made from non-porous or porous material (refer to ASTM F17 for terminology)

Equipment

Seal strength and penetration resistance testing:

Zwick/Roell ZwickiLine Z 5.0

Bubble emission:

Labthink MFY-01 Leak Tester

Burst and creep testing:

Labthink C660M Leak and Seal Strength with fixture:

- LSSD-01P Fixture for Open Package Unrestrained

- LSSD-01F Fixture for Flexible Tube Test