IL-28: Testing of technical cleanliness according to VDA 19 Part 1

When testing technical cleanliness, function-relevant components are specifically examined for particle contamination resulting from the manufacturing process. Even the smallest particles can cause nozzles or filters to clog, valves to jam or bearings to block. On printed circuit boards, a chip can unintentionally connect conductor paths. Components and systems can fail as a consequence.

The RMS Foundation has further expanded its particle analysis capabilities and now also offers technical cleanliness testing according to VDA 19 Part 1 as a service. For this purpose, equipment was procured which makes it possible to carry out so-called cleanliness analyses in accordance with standards. Among other things, the equipment park was expanded with an extraction cabinet from Hydac and a filter analysis system from Jomesa.

The particles are washed off from the component to be examined under defined conditions in the extraction cabinet and then held on an analysis filter.

![]() Jomesa filter analysis system HFD4 (left), Hydac extraction cabinet CTU1040

Jomesa filter analysis system HFD4 (left), Hydac extraction cabinet CTU1040

The filter analysis system serves to automatically count, measure and classify the particles on the filter according to their type (metallic, non-metallic, fibres).

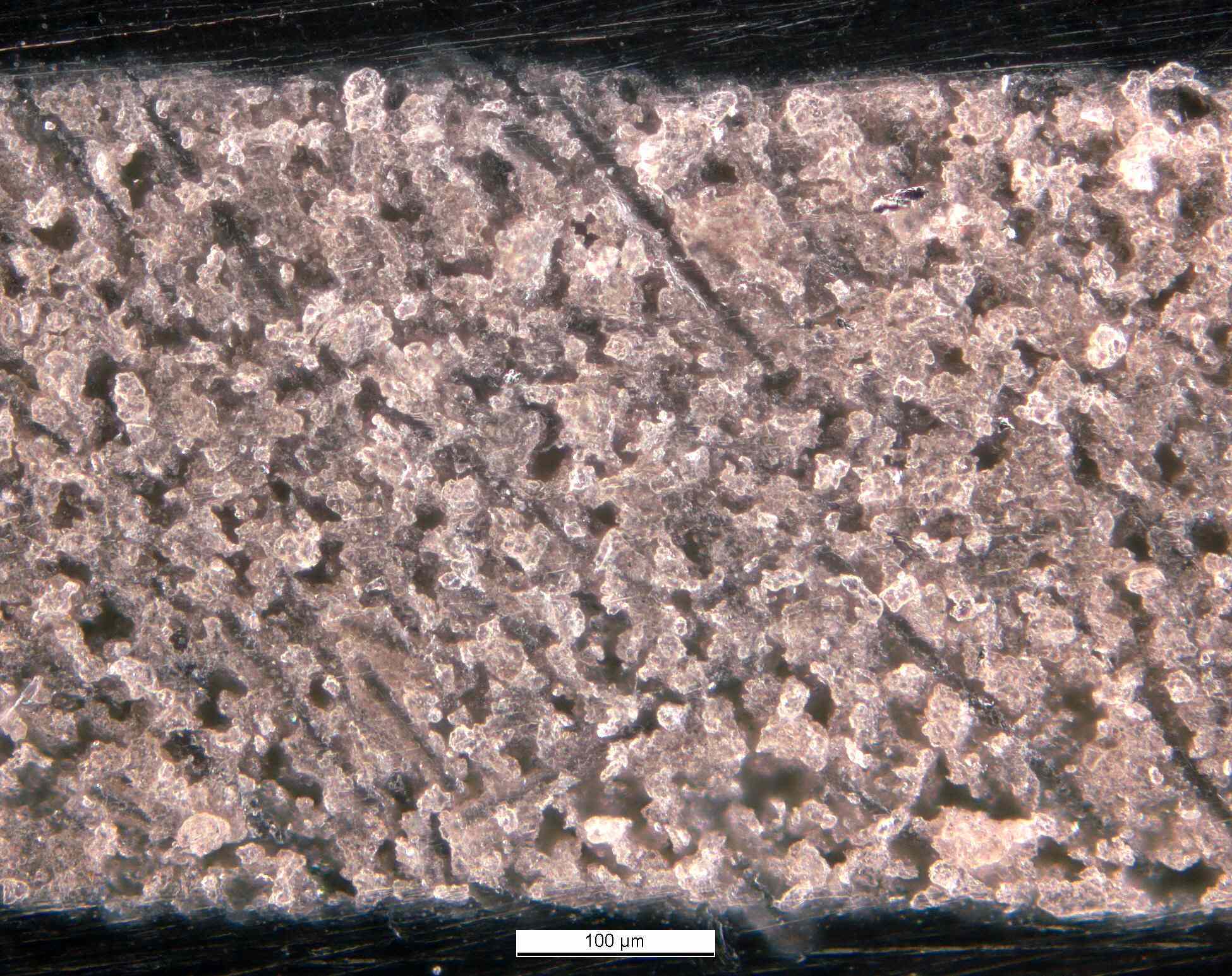

Examples of particles on a 5 µm mesh filter. Metallic particle (left), non-metallic particle (right) and fiber (top)

Examples of particles on a 5 µm mesh filter. Metallic particle (left), non-metallic particle (right) and fiber (top)

The filter analysis system serves to automatically count, measure and classify the particles on the filter according to their type (metallic, non-metallic, fibres).

If required, the particle load can also be determined gravimetrically using an analytical balance. In order to avoid cross-contamination, the cleanliness analyses are carried out in a clean room ISO 14644-1, class 7. Optionally, it is possible to check the composition of selected particles with existing analysis equipment such as SEM/EDX or FT-IR and thus possibly also determine their exact origin. Technical cleanliness has become a fixed quality factor in the customer-supplier relationship, and no longer only in the automotive industry.

How clean are your components?

Equipments:

• Extraction cabinet

Hydac CTU 1040

• Ultrasonic bath Bandelin

Sonorex Digiplus DL512H

• Vacuum filtration unit Sartorius

• Analytical balance

Mettler XPE 2015, 0,01 mg

• Filter analysis system

Jomesa HFD4

• Scanning electron microscope

Zeiss EVO MA 25 with EDX analysis

• FT-IR Microscope Bruker Lumos

Analysis options:

• Testing of technical cleanliness in accordance with VDA 19 Part 1 or customer-specific factory standards

• Further analyses such as SEM-EDX and FT-IR