IL-26: Testing the mechanical seal strength of blister packs

This test method is used to determine the mechanical seal strength when separating the entire cover (lid / membrane) from a rigid or semi-rigid container (blister) according to ASTM F2824 or ASTM F88.

The continuous forces required to separate the lid will be evaluated as well as the maximum seal strength and the work. Furthermore, the mean value can be determined over the entire graph or e.g. from the «valley to valley» area. The lid is separated at a constant angle of 45° over the entire test period. This is implemented with an additional horizontal movement of the blister.

Typical examples of container shapes that could be tested using this method include oval, rectangular and round with single or multiple cavities having a sealed lid. Examples of products packed in these types of containers are: medical and chemical products, ready-to-eat meals, milk products and numerous others.

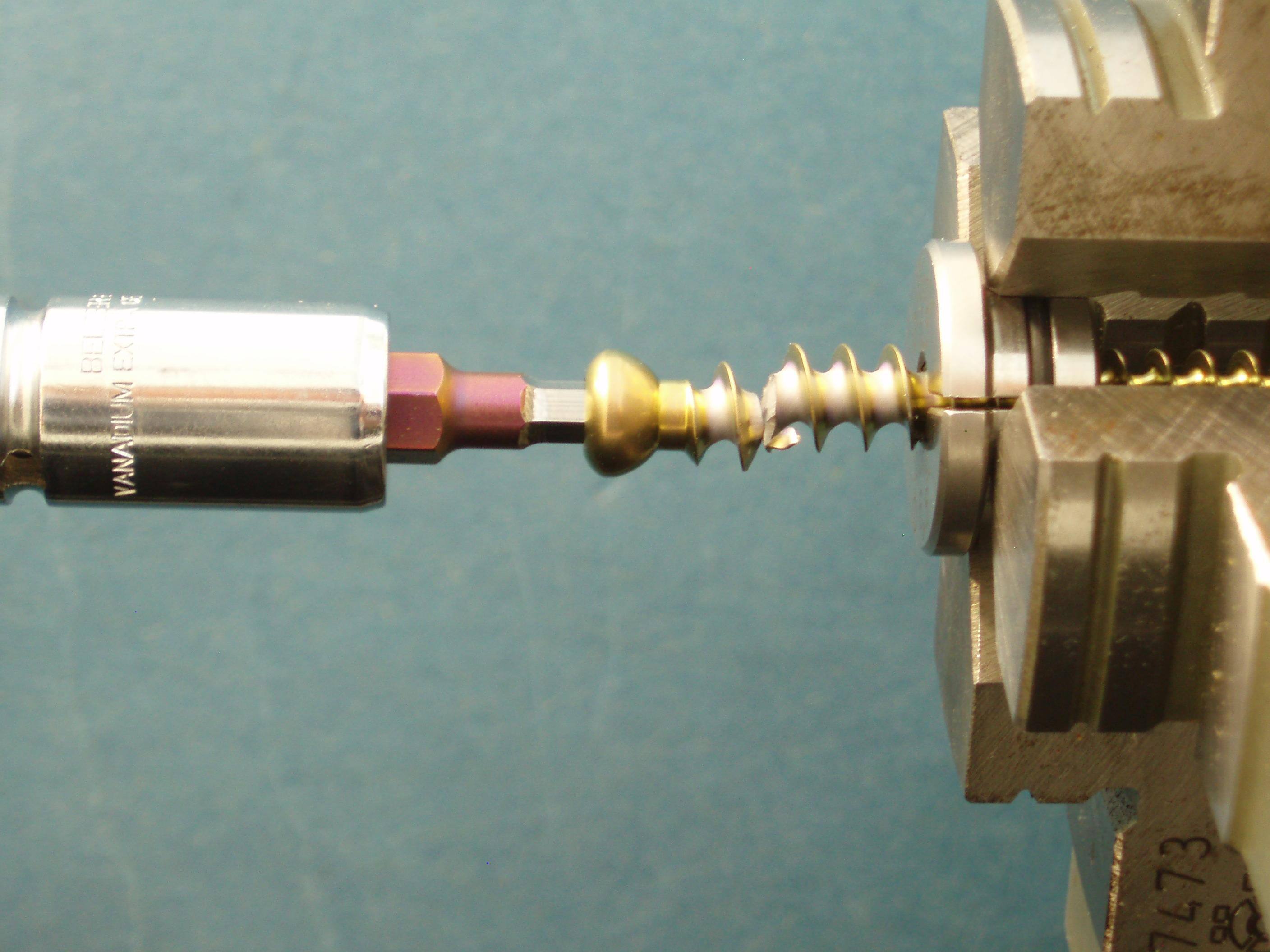

During the test, the sample to be tested (container) is securely fixed to the test setup. The starting point for separating the cover is always the extended tab. The tab is fixed in the grip with a load cell on top. The lid is then separated from the container at a constant speed along the sealed seam of the container (figure 1).

Figure 1: Separating a cover at a constant angle of 45° over the entire test duration.

The forces measured during the test are recorded and can be used graphically and numerically for the test certificate (figure 2).

Figure 2: Force-displacement diagram.

The results gained can serve as an overall assessment for the quality assurance of the packaging. Therefore, it is important to judge the regularity of the seal strength.

Equipment

• Universal testing machine Zwicki Z5.0

• Load cell 100 N

Standards / Methods

• ASTM F2824

• ASTM F88